Aerospace (aircraft) hinges

Bandy Manufacturing’s stamped hinges are engineered for efficiency and effectiveness in aerospace applications. Utilizing a stamping process, these hinges curl around to form the hinge pin hole, creating a lightweight yet robust product. Stamped hinges are designed to have a high strength-to-weight ratio, making them suitable for various aerospace components where weight savings are critical.

More Details and Information

Applications

Stamped hinges are commonly utilized in various aerospace settings, including interior cabin doors, luggage compartments, and service access doors. Their lightweight design makes them an excellent choice for applications where reducing weight is essential without compromising strength or reliability. Additionally, stamped hinges can be produced in high volumes, providing cost-effective solutions for large-scale aerospace projects.

Key Features

– Cost-Effectiveness: The stamping process allows for efficient mass production, making these hinges a budget-friendly option for manufacturers.

– Lightweight Design: Engineered to minimize weight while maintaining structural integrity, stamped hinges are ideal for aerospace applications where every ounce counts.

– Versatility: Available in various sizes and configurations, stamped hinges can be adapted to meet diverse aerospace needs.

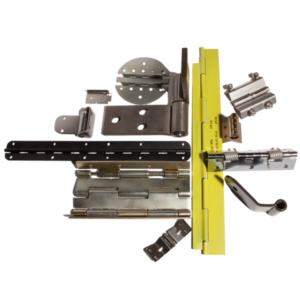

butt hinges

More Details and Information

Applications

Stamped butt hinges are commonly found in various applications, including:

– Interior Doors: Frequently used for interior doors in residential and commercial settings, providing reliable performance with a clean appearance.

– Cabinets and Furniture: Ideal for kitchen cabinets, storage units, and furniture pieces that require a reliable hinge mechanism.

– Industrial Settings: Suitable for lightweight access panels and equipment doors, ensuring ease of use and functionality.

– Medical Facilities: Used in environments requiring sanitation and reliability, such as cabinets and access points in medical settings.

Key Features

– Cost-Effective Production: The stamping process allows for efficient mass production, making these hinges an economical choice for large-scale projects.

– Lightweight Design: Engineered to minimize weight while maintaining structural integrity, stamped butt hinges are ideal for applications where weight savings are critical.

– Versatility: Available in multiple configurations, including plain-bearing, ball-bearing, and concealed-bearing options, stamped hinges can cater to various operational needs.

continuous (piano) hinges

More Details and Information

Applications

Stamped continuous (piano) hinges are widely used across various industries, including:

– Doors and Access Panels: Ideal for both interior and exterior doors, providing smooth operation and durability in high-traffic areas.

– Furniture and Cabinets: Commonly used in kitchen cabinets, storage units, and furniture pieces where reliable hinge mechanisms are essential.

– Industrial Equipment: Suitable for access points on machinery and equipment, ensuring ease of use and longevity.

– Aerospace and Military Applications: Trusted for use in aircraft and military equipment, where durability and compliance with Mil-Spec standards are critical.

– Marine Applications: Engineered to resist corrosion, making them perfect for use in marine environments where exposure to moisture is common.

Key Features

– Versatile Design Options: Our continuous hinges are available in thicknesses ranging from 0.008” (0.2mm) to 0.186” (4.72mm), allowing for extensive customization to meet specific needs.

– Material Variety: We offer continuous hinges in a range of materials, ensuring that you can find the right hinge for your application, whether you require lightweight aluminum or robust stainless steel.

– Custom Configurations: Available with or without holes, free or secured pins, and various finishing options, our hinges can be tailored to your exact specifications.

– Mil-Spec Certification: For applications requiring compliance with military specifications, we provide certified Mil-Spec continuous hinges that meet rigorous quality standards.

– Efficient Supply Chain Solutions: Our streamlined manufacturing process allows for short lead times and rapid quotations, helping you optimize your supply chain.

Precision specialty hinges

More Details and Information

Applications

Stamped precision hinges are widely utilized in numerous sectors, including:

– Furniture and Cabinetry: Commonly used in kitchen cabinets, storage units, and furniture pieces, providing reliable performance with a clean aesthetic.

– Industrial Equipment: Ideal for access panels and machinery, ensuring easy operation and durability in demanding environments.

– Transportation: Used in vehicles and commercial trailers, stamped precision hinges facilitate secure access to compartments and doors.

– Commercial Applications: Frequently found in doors and gates, stamped precision hinges provide dependable functionality in high-traffic areas while ensuring ease of use.

Key Features

– Cost-Effective Production: The stamping process allows for efficient mass production, making these hinges an economical choice for large-scale projects without compromising quality.

– Lightweight Design: Engineered to minimize weight while maintaining structural integrity, stamped precision hinges are ideal for applications where reducing weight is important.

– Material Variety: Available in multiple materials, including Aluminum, Stainless Steel, and Brass, stamped precision hinges can be tailored to meet the specific needs of various applications.

– Customizable Options: Stamped hinges can be easily customized with features such as different lengths, hole patterns, and finishes, providing flexibility for diverse requirements.

INDUSTRIAL HINGES

More Details and Information

Applications

Stamped industrial hinges are widely utilized across various sectors, including:

– High-Traffic Entrances: Commonly used in schools, hospitals, airports, and stadiums, geared-continuous hinges meet the demands of heavy doors while ensuring durability and compliance with fire codes.

– Heavy-Duty Gates: Ideal for wrought iron gates and security applications, providing long-lasting performance and the ability to withstand significant wear and tear.

– Construction and Infrastructure: Used in elevated freeway and railroad viaducts, these hinges help minimize bending stresses and enhance structural integrity.

– Marine and Agricultural Applications: Stamped hinges are often utilized in marine environments and agricultural equipment, delivering reliable performance in harsh conditions.

Key Features

– Cost-Effective Production: The stamping process allows for efficient mass production, making these hinges an economical choice for large-scale industrial projects without sacrificing quality.

– Lightweight Design: Engineered to minimize weight while maintaining structural integrity, stamped industrial hinges are ideal for applications where reducing weight is critical.

– Material Variety: Available in multiple materials, including Aluminum, Stainless Steel, and Brass, stamped hinges can be tailored to meet the specific needs of various industrial applications.

– Customizable Options: Stamped hinges can be easily customized with features such as different lengths, hole patterns, and finishes, providing flexibility for diverse requirements.

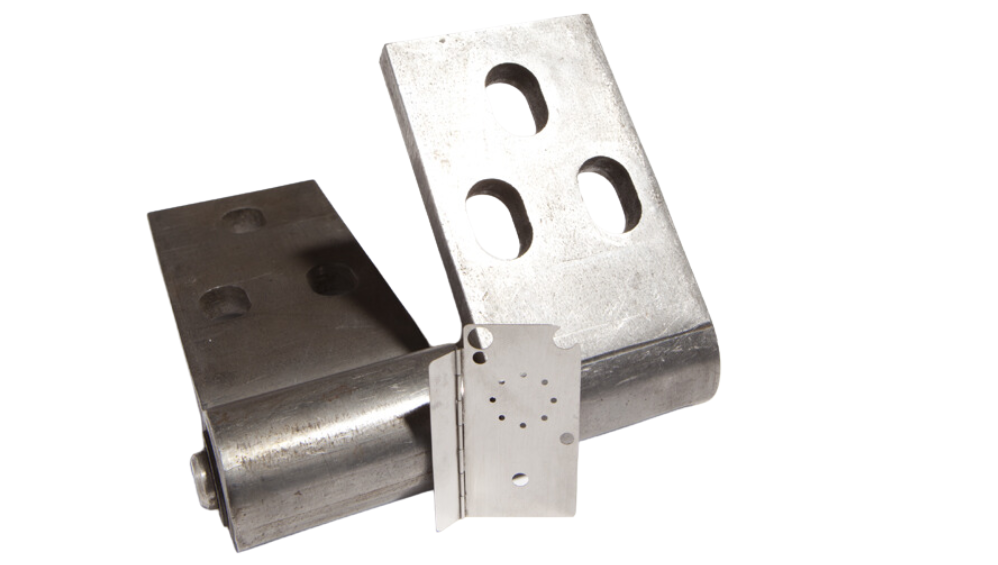

Heavy duty hinges

More Details and Information

Applications

Stamped heavy duty hinges are widely used across various sectors, including:

– Construction Sites: Ideal for heavy doors, gates, and access panels, providing reliable performance in high-traffic areas.

– Transportation: Employed in trailers and commercial vehicles where robust hinges are required to withstand frequent use and heavy loads.

– Military Applications: Used in military vehicles and equipment, ensuring durability and functionality in demanding environments.

– Agricultural Equipment: Essential for farm machinery and implements, where heavy duty performance is crucial for operational efficiency.

Key Features

– Robust Construction: Made from durable materials such as Stainless Steel, Steel, and Aluminum, our stamped heavy duty hinges are engineered to endure exceptional loads and harsh conditions.

– Efficient Production: Utilizing advanced stamping techniques, we can produce hinges with high strength-to-weight ratios, making them suitable for a broad range of applications without compromising performance.

– Customizable Design: Our heavy duty hinges can be tailored to meet specific requirements, including unique dimensions, pin sizes, and knuckle configurations to suit any project.

– Versatile Finishing Options: Available with various coatings and finishes, stamped hinges can be customized to enhance corrosion resistance and aesthetic appeal.

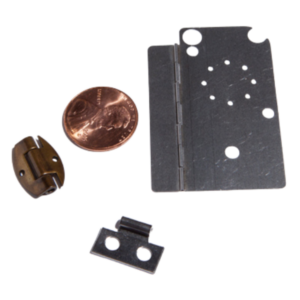

MINIATURE HINGES

More Details and Information

Applications

Stamped miniature hinges are utilized in a variety of specialized settings, including:

– Medical Devices: Essential for compact medical instruments and equipment, providing reliable movement and functionality in critical applications.

– Electronics: Widely used in electronic enclosures and devices, where space-saving designs are crucial for optimal performance.

– Consumer Products: Found in various small appliances and gadgets, ensuring ease of use while maintaining a sleek design.

– Robotics: Employed in miniature robotic components, allowing for precise movement and functionality in confined spaces.

Key Features

– Precision Manufacturing: Our miniature hinges are produced with exceptional accuracy, ensuring reliable performance in compact applications.

– Material Capabilities: We offer material thicknesses down to 0.008” (0.2mm) and pin diameters as small as 0.020” (0.5mm), allowing for the production of extremely compact hinge designs.

– Custom Hole Sizes: With the ability to create holes as small as 0.050” (1.3mm) in diameter, our hinges can cater to intricate design specifications.

– Automated Production: We pride ourselves on offering automated high-speed production for continuous designs with knuckle sizes of 0.25” (6.4mm), ensuring efficiency and consistency in manufacturing.

– Custom Finishing Options: A variety of coatings and finishes are available to enhance durability and meet specific aesthetic requirements, alongside forming and other customizations to suit miniature applications.

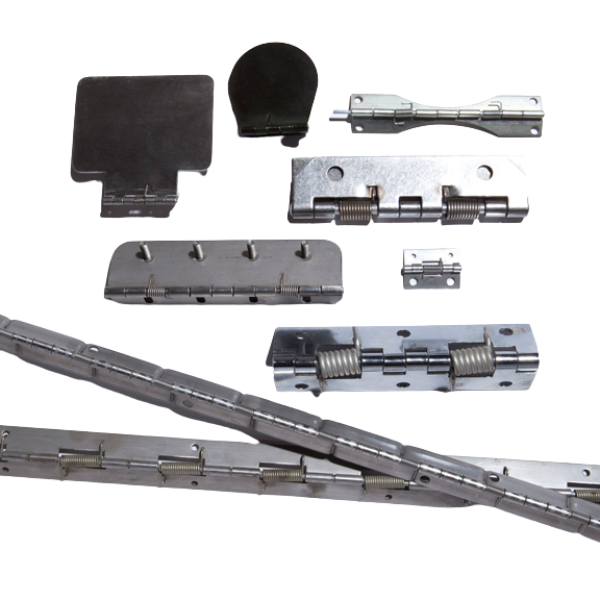

SPRING LOADED HINGES

Stamped spring loaded hinges are designed to provide enhanced functionality by holding doors, panels, and other components securely in either the open or closed position. At Bandy Manufacturing, we specialize in producing high-quality stamped spring loaded hinges that can be customized to meet the specific requirements of your application. With our extensive experience and partnerships with local spring manufacturers, we can source a variety of spring materials, finishes, and torque specifications to deliver the precise tension needed for optimal performance.

More Details and Information

Applications

Stamped spring loaded hinges find use in a variety of applications, including:

– Doors and Gates: Commonly used in residential and commercial settings, these hinges facilitate automatic closing for convenience and security.

– Medical Equipment: Ideal for medical devices and equipment where hands-free operation is essential, providing reliable function in critical environments.

– Electronics: Used in electronic enclosures and devices, allowing for easy access while maintaining a compact design.

– Automotive: Employed in vehicle compartments and access panels, ensuring secure operation and user-friendly access.

Key Features

– Versatile Spring Options: Our spring loaded hinges can accommodate springs of various materials and finishes, allowing for tailored tension and functionality based on your design needs.

– Customization Capabilities: In addition to spring selection, we offer comprehensive customization options such as hole piercing, swaging, forming, and more to meet unique design specifications.

– Robust Construction: Stamped from high-quality materials, our hinges are engineered for durability and reliability, ensuring long-lasting performance in demanding environments.

– Efficient Production: Our advanced manufacturing processes enable us to produce spring loaded hinges quickly and efficiently, providing timely solutions for your projects.