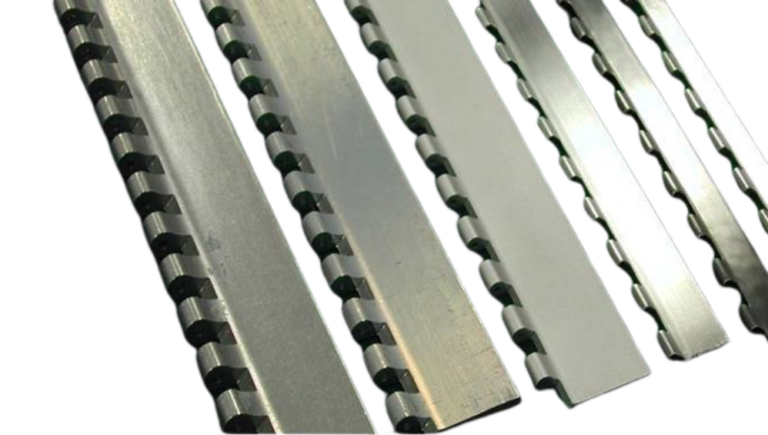

AIRCRAFT/aEROSPACE HINGES

More Details and Information

Applications:

Machined hinges are extensively used in high-stress areas of aircraft, such as landing gear doors, control surfaces, and access panels. Their robust construction is essential for maintaining integrity in extreme conditions, whether in military aircraft, commercial airliners, or space exploration vehicles. These hinges can be customized to fit specific requirements and comply with Mil-Spec standards, ensuring they meet the rigorous quality expectations of aerospace professionals.

Key Features

– Precision Engineering: Each hinge is precisely machined to exact specifications, ensuring consistent performance.

– Durability: Built to withstand the harshest environments, machined hinges offer excellent resistance to fatigue and wear.

– Customization: Tailored solutions are available to meet unique aerospace requirements, including specific dimensions and materials.

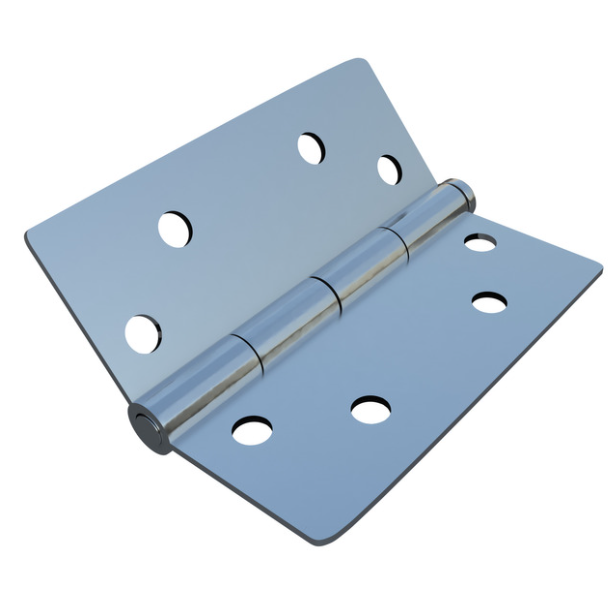

BUTT HINGES

More Details and Information

Applications

Machined butt hinges are widely used in various settings, including:

– Industrial Equipment: Ideal for heavy machinery and equipment access, where reliability and strength are paramount.

– Commercial Doors: Perfect for high-traffic areas, ensuring smooth operation and longevity.

– Marine Applications: Designed to resist corrosion, making them suitable for boats and other marine environments.

– Military and Aerospace: Engineered to meet strict specifications, these hinges are trusted for use in military and aerospace applications.

Key Features

– Precision Engineering: Each machined butt hinge is constructed with exact specifications, ensuring superior alignment and functionality.

– Durability: Made from robust materials like Aluminum, Stainless Steel, or Steel, these hinges are built to withstand heavy loads and harsh environments.

– Customization: We offer a wide variety of modifications, including non-removable pins (NRP) for enhanced security and various finishes to suit specific requirements.

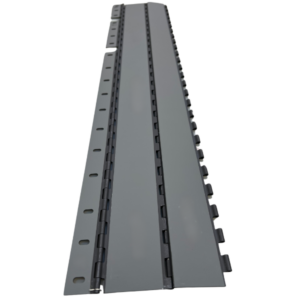

heavy duty hinges

More Details and Information

Applications

Machined heavy duty hinges are utilized in a variety of demanding applications, including:

– Transportation Equipment: Ideal for trailers, trucks, and heavy machinery, providing reliable functionality and strength for high-traffic areas.

– Military Vehicles: Used in armored vehicles and equipment, ensuring durability and performance under extreme conditions.

– Industrial Doors: Commonly found in heavy-duty doors and gates, these hinges support the weight and frequent use of industrial access points.

– Agricultural Machinery: Essential for farm equipment, where robust hinges are required to withstand harsh outdoor environments and heavy loads.

Key Features

– Exceptional Strength: Designed to support heavy loads, our machined hinges are constructed from high-quality materials, including Stainless Steel, Steel, and Aluminum, ensuring durability in demanding environments.

– Precision Engineering: Capable of forming thick materials down to tight knuckles, our machining processes allow for accurate inner diameters without the need for reaming, enhancing the hinge’s overall performance.

– Custom Specifications: We offer a range of capabilities, including material thicknesses up to 0.375” (9.5mm), pin diameters up to 0.625” (15.9mm), and knuckle lengths as long as 4.00” (102mm), with options for additional customization as needed.

– Versatile Finishing Options: Our machined hinges can be customized with various coatings and finishes to meet specific environmental and aesthetic requirements.

INDUSTRIAL HINGES

More Details and Information

Applications

Machined industrial hinges find use in diverse settings, including:

– Aerospace: Utilized in aircraft components and military vehicles, ensuring structural integrity and performance under extreme conditions.

– Medical Facilities: Essential for heavy-duty doors in radiology, oncology, and research labs, these hinges provide seamless operation and reliability.

– Industrial Machinery: Commonly found in access points on heavy machinery, ensuring efficient operation and durability in high-traffic environments.

– Heavy-Duty Gates: Used in wrought iron gates and armored vehicles, machined hinges provide immense load-bearing capacities and long-lasting performance.

Key Features

– Precision Engineering: Each machined hinge is produced to exact specifications, ensuring superior alignment and functionality critical for high-performance applications.

– Material Versatility: Available in a variety of materials, including Aluminum, Stainless Steel, and Steel, these hinges can be tailored to withstand specific environmental conditions and load requirements.

– Enhanced Durability: Designed to endure harsh operational conditions, machined industrial hinges offer exceptional resistance to wear, corrosion, and fatigue, making them suitable for heavy-duty applications.

– Custom Solutions: Machined hinges can be customized with various features, such as non-removable pins (NRP), specific hole configurations, and specialized finishes to meet unique customer needs.

PRECISION SPECIALTY HINGES

More Details and Information

Applications

Machined precision hinges are utilized across a wide array of applications, including:

– Security Systems: Ideal for securing heavy doors, vaults, and gates, machined precision hinges provide the strength needed for high-load capacities and tamper-proof mechanisms.

– High-Traffic Environments: Commonly found in industrial machinery and construction settings, these hinges are designed for durability and reliability in high-use scenarios.

– Aerospace Components: Critical for the functionality of aircraft, machined precision hinges support various segments, including landing gear doors, flaps, and cargo access points.

– Military and Defense: Trusted for use in military applications, machined precision hinges ensure operational integrity in demanding environments.

Key Features

– Precision Engineering: Each machined hinge is crafted to exact specifications, ensuring superior alignment and functionality critical for high-performance applications.

– Material Versatility: Available in a variety of materials, including Aluminum, Stainless Steel, and Brass, machined precision hinges can be tailored to specific environmental conditions and load requirements.

– Durability: Designed to withstand extreme operational conditions, these hinges offer excellent resistance to wear, fatigue, and corrosion, making them suitable for heavy-duty applications.

– Custom Solutions: Machined hinges can be customized with various features, including non-removable pins (NRP), specific hole configurations, and specialized finishes to meet unique customer needs.

MACHINED COMPONENTs

Machined components are precision-engineered parts designed to meet the specific demands of various industries. At Bandy Manufacturing, we specialize in crafting high-quality machined components that ensure optimal performance and reliability. Utilizing advanced machining techniques, we produce components that are tailored to fit the exact specifications of our clients, ensuring seamless integration into their applications.

More Details and Information

Applications

Machined components are utilized in various sectors, including:

– Aerospace: Critical parts for aircraft systems and structures, ensuring safety and performance.

– Automotive: Components for engines, chassis, and transmission systems, providing durability and reliability.

– Industrial Equipment: Parts for machinery and equipment that require high precision and strength.

– Medical Devices: Components used in surgical instruments and devices, ensuring compliance with stringent quality standards.

Key Features

– Precision Engineering: Each component is manufactured to exact tolerances, ensuring superior fit and functionality.

– Material Variety: We offer a wide range of materials, including Aluminum, Stainless Steel, and Brass, to suit diverse operational requirements.

– Custom Solutions: Components can be customized according to unique specifications, including dimensions, finishes, and additional features.

– Rapid Prototyping: Our efficient manufacturing processes allow for quick turnaround times on prototypes and production runs.

HINGE ASSEMBLIES

More Details and Information

Applications

Hinge assemblies are commonly found in:

– Industrial Machinery: Providing access and movement in heavy-duty equipment and machinery.

– Doors and Gates: Used in commercial and residential applications for secure and functional access.

– Aerospace: Hinge assemblies for aircraft doors, access panels, and control surfaces.

– Furniture and Cabinets: Ensuring functionality and accessibility in cabinetry and furniture design.

Key Features

– Robust Construction: Assembled from high-strength materials, our hinges are designed to withstand heavy use and environmental challenges.

– Custom Configurations: Hinge assemblies can be tailored to meet specific operational requirements, including size, load capacity, and finish.

– Smooth Operation: Engineered for seamless movement, our hinge assemblies ensure reliable performance in both commercial and industrial settings.

– Versatile Designs: Available in a variety of styles, including butt hinges, continuous hinges, and specialty designs, to suit various applications.

AIRCRAFT SPARES

More Details and Information

Applications

Aircraft spares are utilized in various aviation settings, including:

– Commercial Aviation: Replacement parts for commercial aircraft to ensure operational efficiency and safety.

– Military Aircraft: Specialized components for military aviation applications, designed for rigorous performance standards.

– Helicopters: Hinges and components used in rotor systems and access doors, ensuring reliability in critical operations.

– Maintenance, Repair, and Overhaul (MRO): Parts for MRO services to maintain and enhance the performance of aircraft.

Key Features

– Aerospace Compliance: All aircraft spares are manufactured in accordance with industry regulations and quality standards.

– High Strength-to-Weight Ratio: Designed to be lightweight yet robust, ensuring optimal performance without adding unnecessary weight to the aircraft.

– Custom Fabrication: Components can be tailored to specific aerospace applications, including unique dimensions and features.

– Durability: Engineered to withstand extreme conditions, including temperature variations and mechanical stress.